3D modeling and printing

A few years ago, 3D printing was something surprising for most people, but today it is becoming more and more widespread.

In order to obtain an object using a special printer, the preliminary creation of its three-dimensional model and its optimization are required.

Three-dimensional modeling and printing on 3D printers, without a doubt, has opened new horizons in the production sector, both on an industrial scale and in the production of single copies at home.

The easiest option is to use a ready-made model to create a three-dimensional object. However, even the presence of a large number of such options in the vastness of the World Wide Web may seem insufficient for your purposes. If you need something exclusive, you will have to create such a model yourself, or entrust it to visualizers.

Today, 3D modeling of products and printing of objects on printers is not yet a procedure massively introduced into the industry. However, the number of materials that can be used in 3D printing technology is increasing every year.

Plastics, flexible solutions, ABS and much more – this will not surprise anyone. The most amazing is the 3D printing of metals. Such material is used not only to create metal parts, but also in issues such as 3D modeling of jewelry, creating decorative elements, etc.

Today, everyone has the opportunity to order visualization in 3D MAX, Maja and other applications with further metal printing.

What is making 3D printer models? 3D modeling today is used not only to create three-dimensional projections of some objects, but also as a basis for realizing this object with the help of special modern technology. However, a full-fledged three-dimensional model, suitable for subsequent printing, should be created in accordance with certain conditions – only then it will be possible to obtain the desired result.

Prospects for printing metals

Metal printing is a promising area of activity, since parts created in this way have incomparable advantages compared to products made on CNC or by casting. There are two main advantages of three-dimensional printing:

- Minimization of waste. For example, in the aircraft industry, about 90% of all metal and plastic products are discarded. In industries where 3D printing is involved, only 30% of all metal and plastic materials are recyclable.

- 3D printing with metals does not require complex accompanying processes: in fact, the only equipment for production is the 3D printer itself. Such production does not require large expenditures of electricity; products can be lighter than parts manufactured in a traditional way. At the same time, the strength and reliability of the parts are not inferior.

Thus, the use of 3D printing in the aviation industry can not only save production costs on design features but also reduce the weight of structures (and therefore reducing the amount of fuel consumed).

In any activity that involves creating something, the selection of the right materials is paramount. To three-dimensional modeling, this applies in the first place. To understand how much 3D visualization costs, you need to clearly understand all levels of complexity and scale of work.

This also applies to such services as 3D scanning, creation of animated three-dimensional scenes, product visualization: the price of these services largely depends on the detail, quantity and complexity of objects.

3D computer visualization allows to create three-dimensional objects with any physical properties, in fact, they are ideal, their physical and chemical properties can only be modeled. However, in practice, the physical properties of the material are the most important characteristics that play a crucial role in the liquidity of the final product.

Gears, transfer rollers and much more should have high strength, while belts, springs, etc. – on the contrary, they must be flexible.

Physical and chemical properties – the concept is very extended. This includes: melting point, boiling point, viscosity, density, flexibility, elasticity, concentration, emission, fluidity and much more.

3D printingwith metal in household conditions

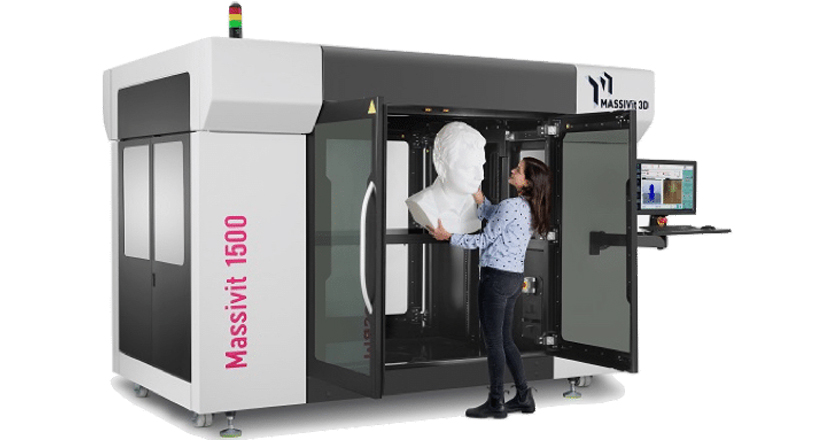

In order to carry out three-dimensional printing with metals, extremely high temperatures, a perfect industrial ventilation system are needed.It is not possible to use FDM 3D systems for metal printing (at least for today). Large industrial machines that allow printing with metal cannot be used in domestic conditions. In addition, such devices cost at least 200 thousand dollars.

The upper limit of the cost of such machines is almost unlimited.The best way to get as close as possible to printing with metallic materials is to use the so-called filaments – substances containing plastic and metal particles.Examples of such materials are ColorfabbBronzefill and Best filament Bronze.

Filaments contain a high percentage of metal powder, but also a lot of plastic. This allows to print at low temperatures, with which conventional three-dimensional printerswork.

Types of materials in 3D printing

When engaging in 3D printing and creating various parts, one often has to deal with materials such as ABS and PLA. These types of polymers are the most common, but not all of their properties fully satisfy the requirements.

Flex today is not yet so promoted and advertised, for these reasons, many 3D printers are still unfamiliar with it, however, you should know that this is an excellent industrial elastomer, characterized by increased mechanical performance.

It is actively used in the creation of decorative products, protective coatings, flexible gaskets (including in the automotive and plumbing industries), soles, etc.

Advantages and disadvantages of flex

The main properties of flex are:

- excellent adhesion to the surface;

- high degree of elasticity;

- resistance to mechanical damage and wear, durability;

- the ability to apply in the temperature range: from -60 to +80 degrees;

- good sintering ability (softening and compaction during heating-cooling).

Of course, the material has its drawbacks. The main disadvantage is the widespread vulnerability of elastomers – low resistance to contact with solvents, acetones, hydrocarbons (e.g. gasoline), and acids.

Flex is a product of many manufacturers. The material is environmentally friendly, does not emit toxic substances when printed, it is presented in various colors, most in bright and colorful colors. Elastomers are different – there are harder types and softer ones, depending on what properties the object should have.

Leave a Reply

Want to join the discussion?Feel free to contribute!